With supply chain management at the forefront, get ready to dive into a world where efficiency meets strategy, and success is the ultimate goal. From defining the concept to exploring real-world examples, this journey promises to be enlightening and engaging.

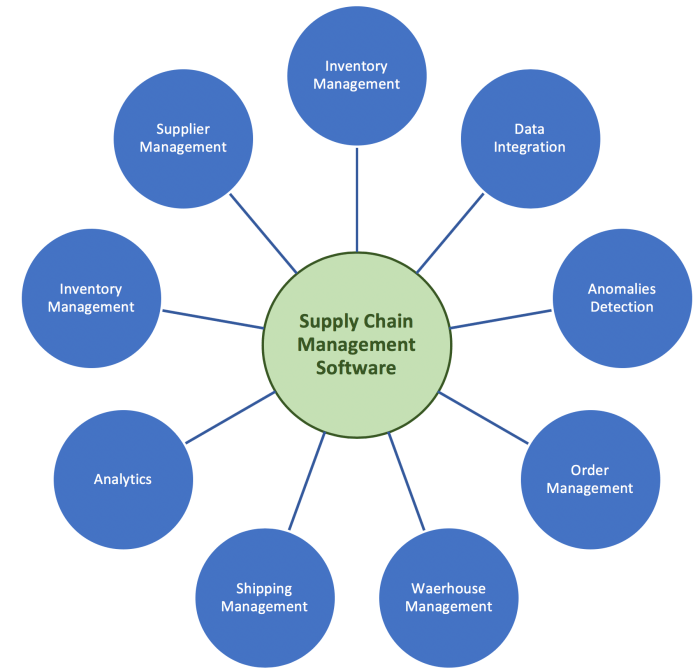

Overview of Supply Chain Management

Supply chain management is the process of overseeing and optimizing all activities involved in the production and distribution of goods or services.

Effective supply chain management is crucial for businesses to ensure efficient operations, reduce costs, minimize risks, and meet customer demands.

Key Elements of Supply Chain Management

- Planning: Forecasting demand, setting objectives, and developing strategies to meet goals.

- Sourcing: Finding and selecting suppliers, negotiating contracts, and managing supplier relationships.

- Production: Manufacturing goods, managing inventory, and ensuring quality control.

- Logistics: Managing transportation, warehousing, and distribution of products.

- Customer Service: Ensuring customer satisfaction, handling returns, and managing communication.

Examples of Successful Supply Chain Management Strategies

One notable example of successful supply chain management is Amazon. The company has implemented advanced technology, such as robotics and AI, to optimize its warehouse operations and delivery processes. This has allowed Amazon to offer fast and reliable shipping to customers, leading to high levels of customer satisfaction and loyalty.

Another example is Walmart, known for its efficient supply chain management practices, which include strategic partnerships with suppliers, inventory management systems, and a strong focus on sustainability. These strategies have helped Walmart reduce costs, improve product availability, and enhance overall operational efficiency.

Types of Supply Chains

Supply chains can be categorized into different types based on their strategies and structures. Each type has its own set of advantages and disadvantages, making them suitable for various industries and situations. Let’s explore the different types of supply chains and their impact on global events.

Lean Supply Chain

A lean supply chain focuses on minimizing waste and maximizing efficiency in operations. By reducing excess inventory and streamlining processes, companies can save costs and respond quickly to changing customer demands. Industries such as automotive and electronics benefit from lean supply chains due to their high-volume production and need for precision.

Agile Supply Chain

An agile supply chain is designed to adapt quickly to market changes and customer preferences. It emphasizes flexibility and responsiveness, allowing companies to adjust production schedules and product designs rapidly. The fashion and retail industries often utilize agile supply chains to keep up with fast-changing trends and seasonal demands.

Responsive Supply Chain

A responsive supply chain combines the strengths of both lean and agile approaches. It aims to be efficient while also being able to respond rapidly to disruptions or unexpected events. Companies in the pharmaceutical and healthcare sectors rely on responsive supply chains to handle emergencies and ensure timely delivery of critical supplies.

Impact of Global Events, Supply chain management

Global events such as natural disasters, pandemics, or trade disputes can significantly impact the choice of supply chain type. For instance, during a pandemic, companies may shift towards a more responsive supply chain to manage disruptions in production and distribution. Trade tensions between countries may lead companies to reevaluate their lean supply chain strategies to reduce reliance on specific regions.

Supply Chain Planning

Supply chain planning is a crucial process that involves determining the best way to fulfill customer demand while minimizing costs and optimizing efficiency in the supply chain.

Process of Supply Chain Planning

Supply chain planning typically involves forecasting demand, setting inventory levels, determining production schedules, and coordinating transportation and logistics to ensure products are delivered to customers on time.

Role of Demand Forecasting

Demand forecasting plays a key role in supply chain planning by helping companies predict customer demand for products. By accurately forecasting demand, companies can adjust their production, inventory, and distribution strategies to meet customer needs efficiently.

Importance of Inventory Management

Effective inventory management is essential in supply chain planning to ensure that the right amount of inventory is available at the right time. By optimizing inventory levels, companies can reduce carrying costs, minimize stockouts, and improve customer satisfaction.

Impact of Technology

Technology has transformed supply chain planning processes by enabling real-time visibility into inventory levels, demand forecasting, and transportation logistics. Advanced analytics, artificial intelligence, and automation tools have helped companies improve forecasting accuracy, optimize inventory levels, and streamline supply chain operations.

Logistics and Transportation in Supply Chains

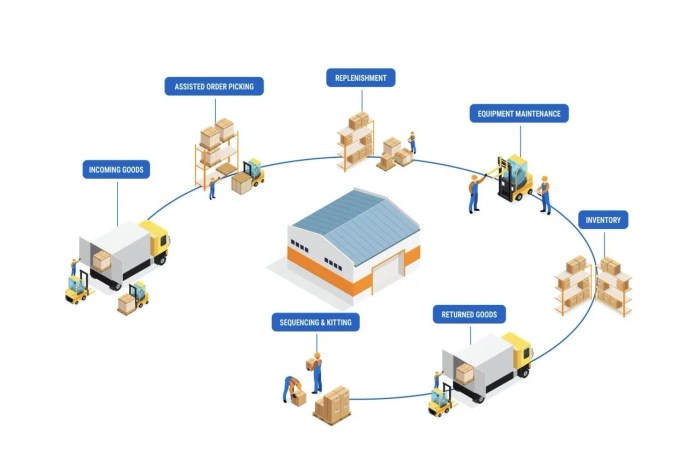

Logistics and transportation play a crucial role in supply chain management, ensuring the smooth flow of goods from the point of origin to the final destination. Efficient logistics and transportation processes are essential for reducing costs, improving customer satisfaction, and maximizing overall supply chain performance.

Significance of Logistics in Supply Chain Management

Logistics involves the planning, implementation, and control of the movement and storage of goods, services, and information within a supply chain. It includes activities such as inventory management, order processing, warehousing, and transportation. Effective logistics management helps companies streamline operations, minimize delays, and optimize resources, leading to enhanced productivity and profitability.

Impact of Transportation Decisions on Supply Chain Efficiency

Transportation decisions directly impact the efficiency of supply chains by influencing delivery times, costs, and customer satisfaction levels. Choosing the right transportation mode, route, and carrier can significantly affect the overall performance of a supply chain. Efficient transportation management ensures timely deliveries, reduces transportation costs, and enhances flexibility to adapt to changing market demands.

Role of Warehousing and Distribution Centers in Logistics

Warehousing and distribution centers serve as crucial nodes in the logistics network, facilitating the storage, consolidation, and distribution of goods. These facilities enable companies to manage inventory levels, fulfill customer orders, and coordinate the flow of products throughout the supply chain. Effective warehousing and distribution center operations help optimize inventory turnover, reduce lead times, and enhance order fulfillment capabilities.

Examples of Innovative Transportation Solutions

Innovative transportation solutions, such as drone delivery, autonomous vehicles, and real-time tracking technologies, are revolutionizing supply chain performance. For instance, companies like Amazon are leveraging drone technology to expedite last-mile deliveries, while autonomous vehicles are enhancing transportation efficiency and reducing carbon emissions. Real-time tracking systems provide visibility into shipment status, allowing companies to proactively address potential issues and improve customer satisfaction.

Supplier Relationship Management: Supply Chain Management

Supplier Relationship Management (SRM) is the process of strategically managing interactions with suppliers to maximize value and minimize risks. It is crucial for ensuring a smooth and efficient supply chain operation.

Importance of SRM

Supplier Relationship Management is important for fostering long-term partnerships with suppliers, improving product quality, reducing costs, and enhancing supply chain flexibility and responsiveness. By building strong relationships with suppliers, companies can gain a competitive advantage in the market.

- Establishing trust and mutual respect

- Communicating effectively and transparently

- Setting clear expectations and performance metrics

- Resolving conflicts promptly and fairly

Strong supplier relationships can lead to better collaboration, innovation, and overall supply chain performance.

Supplier Collaboration for Efficiency

Collaborating with suppliers can help streamline processes, reduce lead times, improve inventory management, and enhance overall supply chain efficiency. By working closely with suppliers, companies can better anticipate demand fluctuations and respond quickly to changes in the market.

- Sharing information and data in real-time

- Coordinating production and delivery schedules

- Co-creating value-added solutions

- Implementing joint improvement initiatives

Successful SRM Practices

One real-world example of successful supplier relationship management is Apple Inc.’s partnership with Foxconn, its main manufacturing supplier. By collaborating closely with Foxconn and investing in supplier development programs, Apple has been able to ensure high product quality, timely delivery, and continuous innovation.

- Regular performance reviews and feedback sessions

- Long-term contracts with incentives for performance improvement

- Investing in supplier training and development programs

- Implementing risk management strategies for supply chain disruptions

Sustainability in Supply Chain Management

In today’s global business landscape, sustainability has become a crucial aspect of supply chain management. Companies are increasingly recognizing the importance of integrating sustainable practices into their supply chains to not only reduce environmental impact but also to meet the growing demand for ethical and responsible business operations.

Importance of Sustainability in Modern Supply Chains

- Reducing carbon footprint: By implementing sustainable practices such as using eco-friendly packaging materials and optimizing transportation routes, companies can significantly reduce their carbon footprint.

- Enhancing brand reputation: Consumers are becoming more environmentally conscious, and companies that prioritize sustainability in their supply chains are perceived more favorably by customers.

- Cost savings: Sustainable practices can lead to cost savings in the long run through energy efficiency improvements, waste reduction, and streamlined processes.

How Companies Integrate Sustainability Practices

- Supplier selection: Companies are increasingly partnering with suppliers who adhere to sustainability standards and practices, ensuring that the entire supply chain is aligned with sustainable goals.

- Green logistics: Implementing eco-friendly transportation methods, such as using electric vehicles or optimizing delivery routes, can reduce emissions and environmental impact.

- Recycling and waste management: Companies are focusing on recycling materials and implementing effective waste management strategies to minimize environmental impact.

Benefits of Sustainable Supply Chain Management

- Long-term viability: Companies that prioritize sustainability are better positioned to adapt to changing regulations and consumer preferences, ensuring long-term business viability.

- Risk mitigation: Sustainable practices can help mitigate risks related to environmental disasters, regulatory non-compliance, and reputational damage.

- Enhanced stakeholder relationships: By demonstrating a commitment to sustainability, companies can strengthen relationships with customers, suppliers, and other stakeholders.

Examples of Companies Leading in Sustainable Initiatives

- Patagonia: Known for its commitment to environmental sustainability, Patagonia has implemented various initiatives such as using recycled materials in its products and promoting fair labor practices.

- Unilever: Unilever has set ambitious sustainability goals, including achieving net-zero emissions across its value chain by 2039 and ensuring that all its products are recyclable or reusable by 2025.

- Walmart: Walmart has made significant strides in sustainability, aiming to achieve zero waste in its operations and sourcing 20% of its energy from renewable sources by 2025.